INDUSTRIAL WORKING CENTERS & MACHINERIES

High Performing Solutions for the Industry and the Professional Centers

EXPERIENCE AND KNOW-HOW TO MAKE THE DIFFERENCE

High-quality key processing machines and workstations specifically designed to handle and process different types of keys through fully automated processes and top-quality results with centesimal tolerances. Our solutions are developed and based on our daily tests and experiences in all our production centres. A team of engineers is fully dedicated to the continuous research and improvement of innovative technologies applied to key handling and processing, and to the know-how of Silca's daily key production.

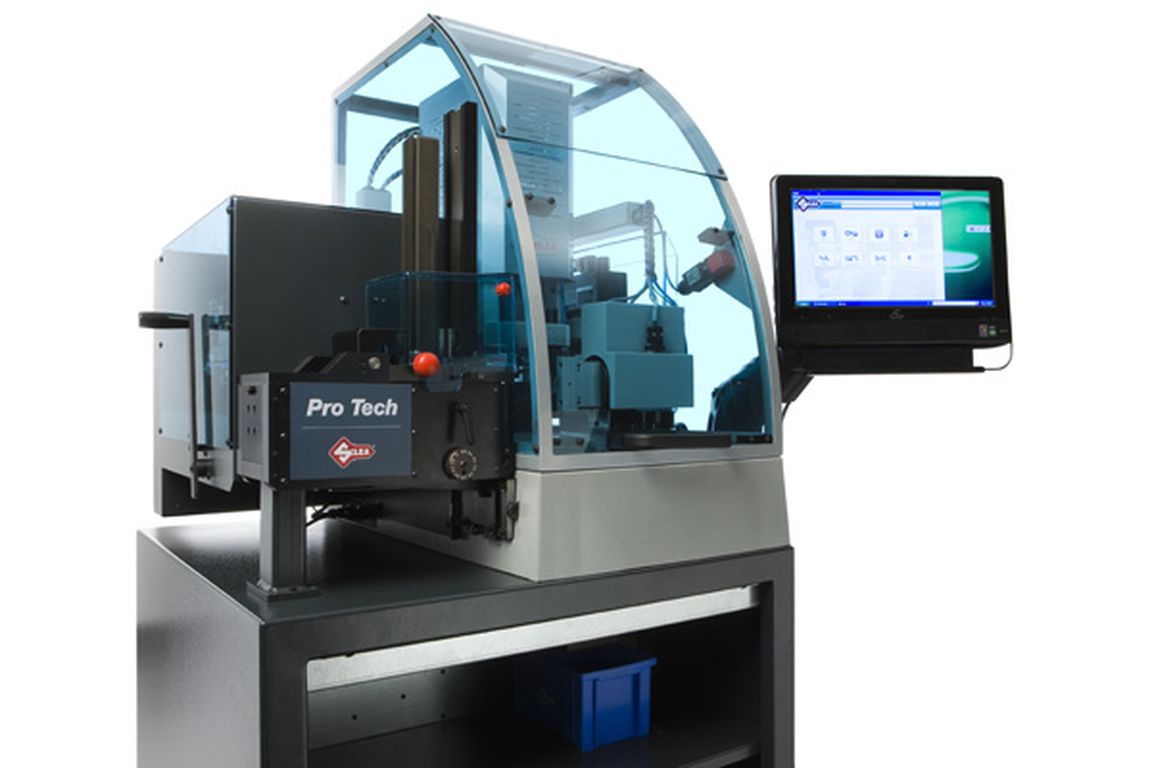

PROTECH RANGE

Protech and Protech Plus and all family models a real concept and not just a simple products. protech family represent the ideal solution not only for Specialist Key-Cutting Centres or Master Key System Manufacturers, but also for all those who organize and manage the production of keys in significant quantities or run round-the-clock key-cutting services, and anyone who wishes to optimize the management of his business.

SEMI INDUSTRIAL SILCA SOLUTIONS

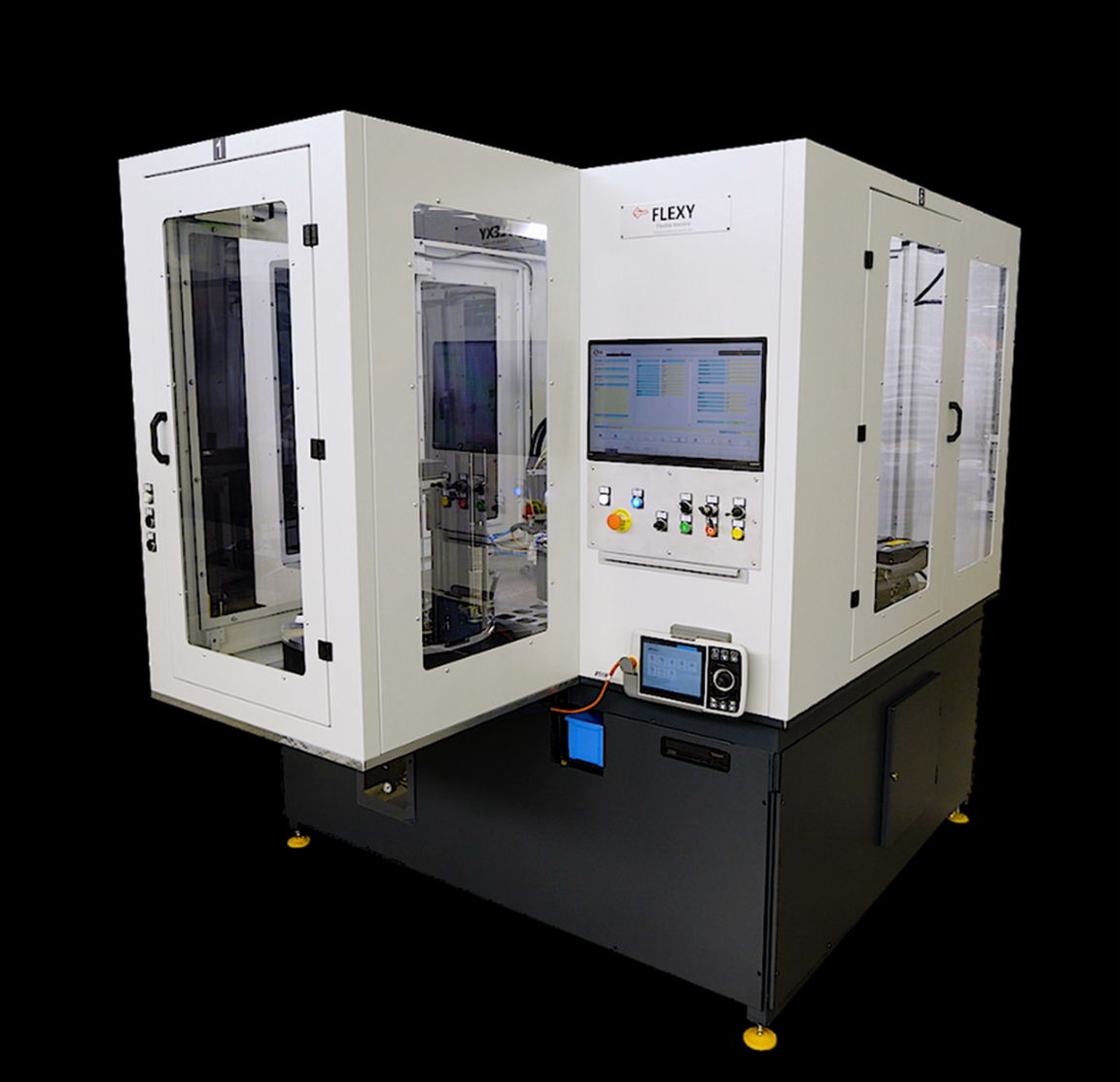

FLEXY

Working center fully customizable according to the needs of the customer user. The station can also process keys of different types without requiring specific setup. The machine is equipped with an anthropomorphic robot that moves the keys to the different work stations. Designed to allocate 3 units: one dedicated to chip removal: milling, punching and blanking, a marking unit to close with brushing and unloading. The anthropomorphic robot is guided by a software entirely developed by the company, Silca Key Bitting, which is able to automatically change the key pick-up and deposit positions without requiring any machine setup.

INDUSTRIAL SOLUTIONS

KDM 304

KDM304 Industrial linear station featuring 10 freely modular stations dedicated to the internal and external track encryption of automotive keys. Equipped with a real time processing control system, via camera, it is also designed to carry out customised bagging with the details of the key insert so as to enable unambiguous and error-free association to the cylinder of the corresponding vehicle in the production plants. Quick and precise clamp and tool change. Centesimal machining accuracy with precise removal of machining residues. Fast, optimised and customisable set-up for different key sizes. Also available with optional camera-controlled automatic loading with zero setup parameter.

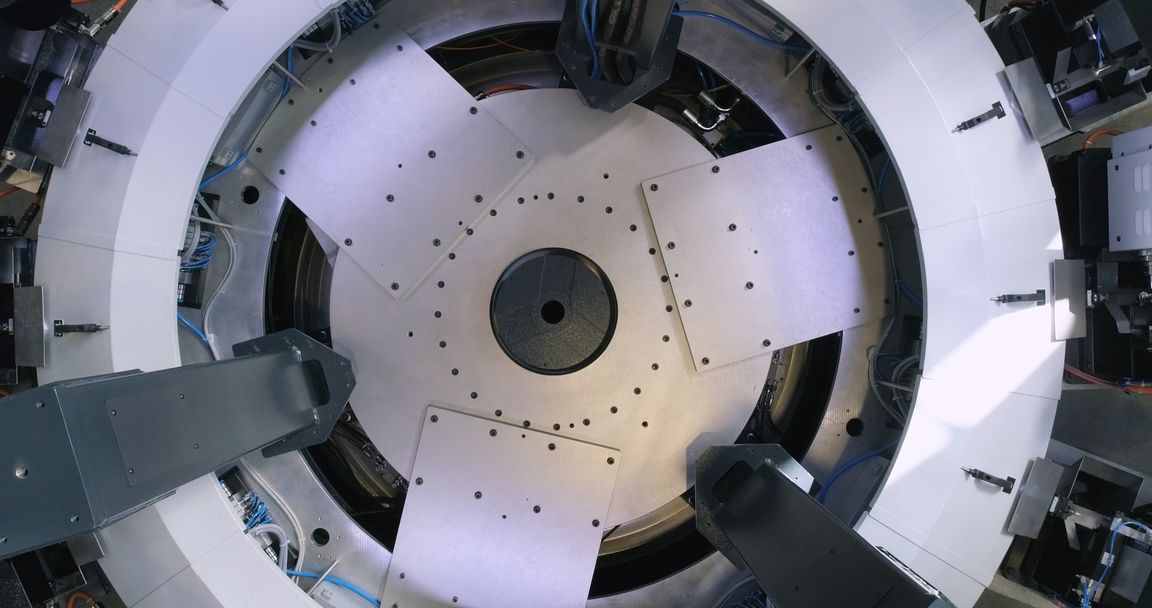

ROTARY TABLE INDUSTRIAL SOLUTION - RT206

RT206 Industrial rotary table station, 10 freely modular workstations handling chip removal machining. Designed to operate with cutting strategies that minimise the presence of metal residues due to key machining. The machine controls machining by means of touch probes, and can machine different materials and alloys, such as steel, silver nickel, brass and aluminium. Super fast clamp and tool changeover times. Automatic loading option with zero set-up camera available.

INDUSTRIAL BITTING STATION - KB101

Industrial rotary table station with 4 different stations dedicated to flat key encryption. The solution involves the encryption station being equipped with a universal key alignment system and a set of automatic key position controls at the tip. The KB101 solution optimises key marking with different systems: laser, scratch or microdot marking. Key brushing operations are managed precisely and perfectly as well as key ringing operations also managed automatically. Two options are available to further enhance machine performance. You can choose the automatic loading option with zero set-up camera or the key unloading option with which you can customise the unloading into cells, belts or boxes according to your needs.

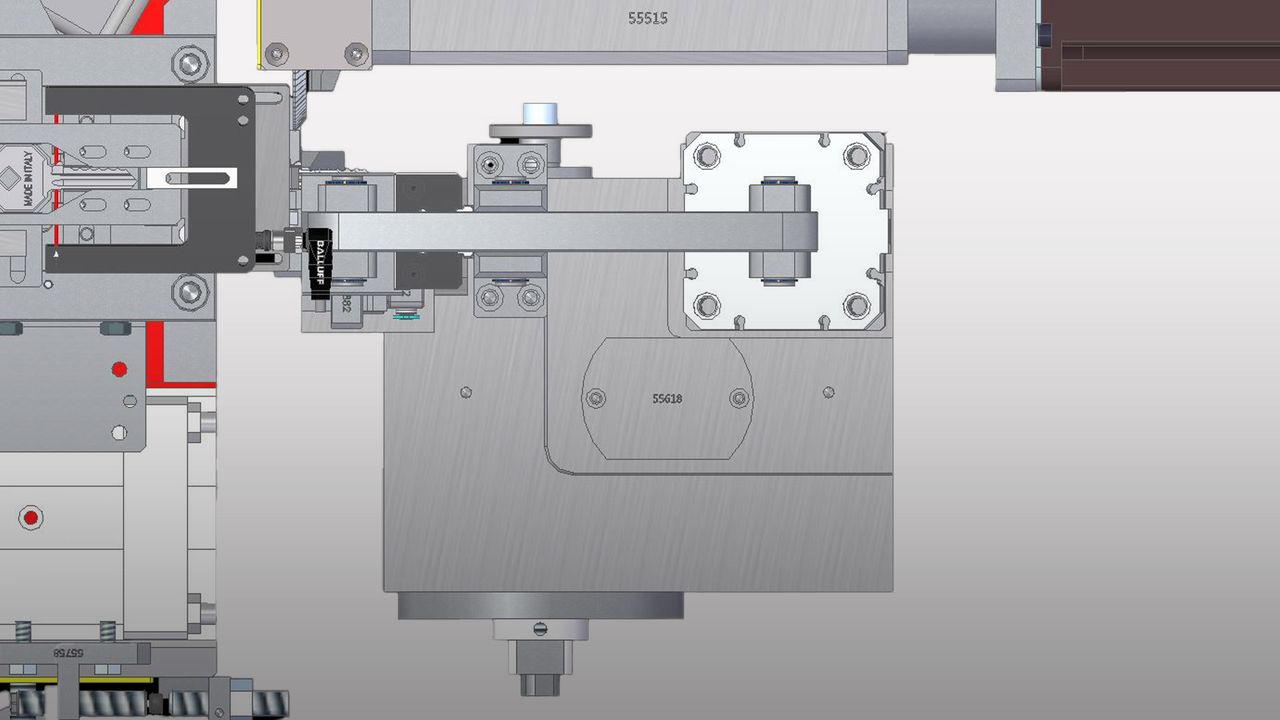

KEY DRILLING & BITTING INDUSTRIAL STATION - KDBM105

KEY DRILLING & BITING STATION - KDBM105 Linear industrial station with 12 freely combinable stations for drilling and biting keys. The station operates different types of marking with absolute precision: laser, scratch or microdot. The station performs key ringing operations. all operations are performed with camera control. The clamp and tool change is designed to be fast and precise. All setups have been imagined and designed to be fast and uncertainty-free. The station is compatible with the optional automatic camera-controlled zero set-up.

KDM INDUSTRIAL STATION

Industrial linear station, freely composable, for machining different key types in CNC mode. The station offers the possibility of working on 4 axes in CNC mode. It is possible to use an optional with automatic key loading with zero-set-up camera. Deburring and brushing processes can be customised on request. Marking is carried out with different technologies: laser, scratch and microdot. Clamp and tool change is fast and can be customised and optimised for different key sizes. the station is equipped with a ringing and bagging unit. Machining is jointly monitored via camera and mechanical touch probes; tool status is also checked.

CONTACT US TO FIND THE RIGHT SOLUTION FOR YOUR NEEDS

A Professional Team is at your disposal to listen and interpret your Company's production needs.